Enabling Real-Time Methane Monitoring:

How QLM Integrated the Robustel R1520 Global to Power its Advanced LiDAR System

Case Study – Fast Facts

Location

UK, Global Client Base

Industry

Industrial IoT, Environmental Monitoring

Product(s)

End Customer

QLM – https://qlmtec.com/

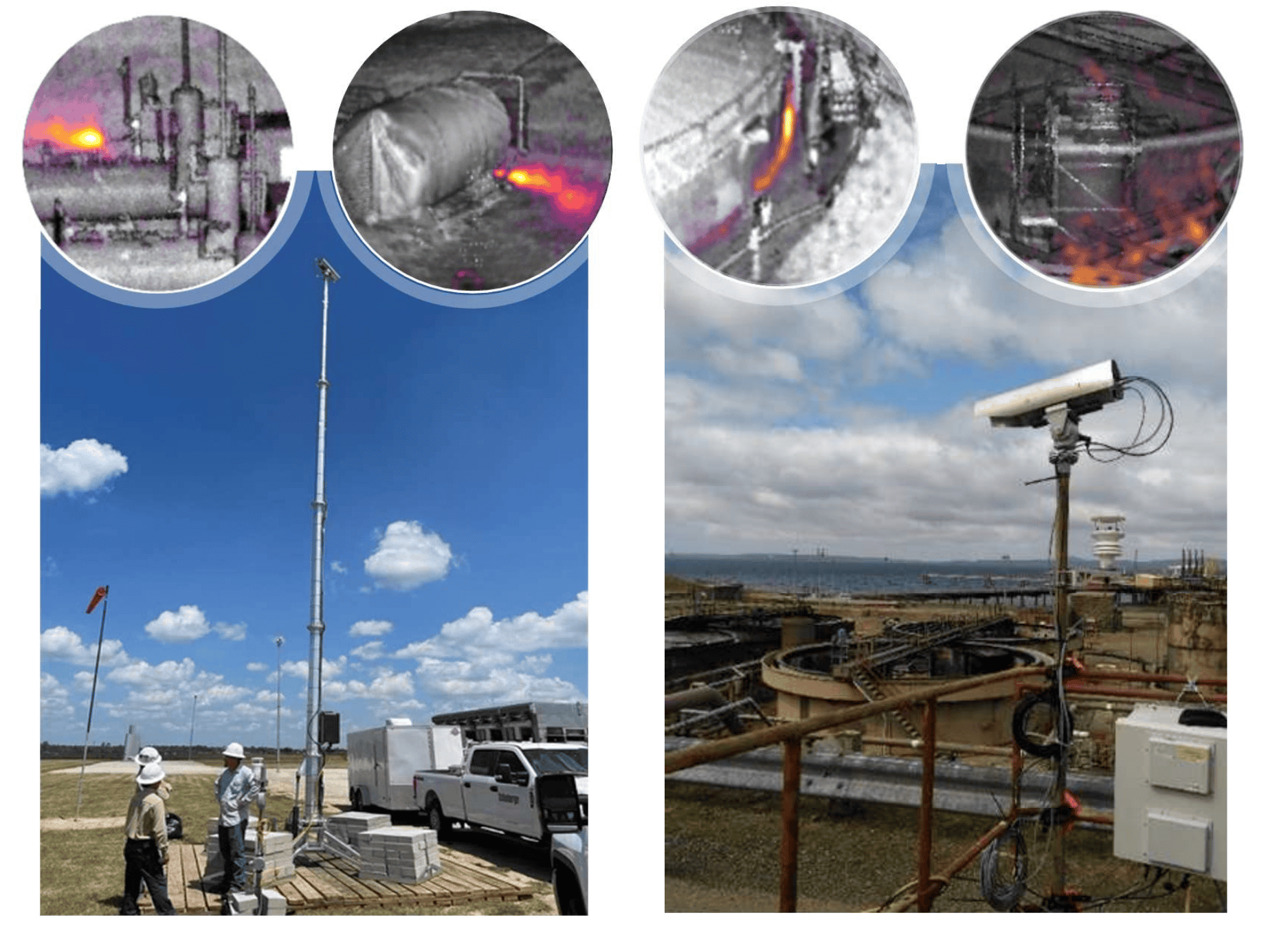

QLM Technology has developed a gas sensing LiDAR system designed to detect, visualise, locate, and quantify gas emissions, including methane, using a combination of LiDAR and gas absorption spectroscopy. The system is intended to support real-time methane monitoring and give operators actionable data for identifying, quantifying, and responding to emissions events.

For organisations managing industrial sites and distributed assets, methane monitoring is both a safety issue and an emissions management issue. QLM’s deployments are designed to support faster identification of leaks and better visibility into emission patterns over time, helping teams shift from reactive site visits to more data-driven response.

Challenges

QLM’s LiDAR system addressed the sensing problem, but required a robust communications backbone to transmit high-quality data from remote sites, support real-time monitoring and alerts, and operate reliably in industrial conditions. Connectivity can be the limiting factor in remote and harsh environments, especially when systems need to run unattended for long periods. QLM also needed a cost-effective 4G solution aligned with global deployment requirements, where certification and regional acceptance materially affect rollout speed.

Results

By embedding the Robustel R1520 Global into its field system, QLM established resilient cellular telemetry from the LiDAR platform to QLM’s cloud environment, supporting real-time data transmission and remote management in challenging deployment contexts. RCMS supports ongoing monitoring and management of deployed routers, and RobustVPN supports remote access workflows without requiring fixed IP arrangements from SIM providers. Together, this strengthened QLM’s ability to deliver actionable methane insights while reducing the operational friction of maintaining distributed deployments.

Turning methane monitoring into an always-on field capability

Methane is a high-impact greenhouse gas and a serious safety concern in multiple industries, from oil and gas facilities to waste and wastewater sites. Detecting and quantifying emissions early matters, but many monitoring methods still depend on manual surveys or can be difficult to sustain across remote, distributed assets. In practice, one of the weakest links is often not the sensor, but whether the system can reliably transmit field data and remain operable without constant site access.

QLM’s LiDAR-based approach is designed to generate real-time methane concentration and plume information that teams can use to respond faster and build a clearer picture of emissions over time. But to translate sensing capability into operational value, the system needs dependable telemetry that can handle industrial conditions, variable coverage, and the realities of multi-country deployments. QLM needed a connectivity layer that was rugged, manageable at scale, and practical to deploy across jurisdictions.

Business Challenges

Methane monitoring programmes rarely fail because teams don’t care; they fail because it is hard to sustain consistent coverage across sites, seasons, and operating conditions. Many assets are remote, access is costly, and emissions can be intermittent. QLM’s challenge was to ensure its LiDAR system could deliver continuous value in the field: dependable data transport, reliable uptime, and remote operability, without turning every deployment into a bespoke connectivity project.

1. Reliable telemetry from remote and harsh sites

Monitoring systems deployed in remote agricultural sites, industrial facilities, and utility environments are often constrained by connectivity limitations. When a system cannot reliably send data, it cannot support real-time monitoring or timely alerts. Even short outages can reduce trust in the monitoring programme and delay response.

Operationally, this creates a familiar cycle: more manual checks, more scheduled site visits, and more time spent validating whether “no alert” means “no leak” or simply “no connectivity.” QLM needed an industrial connectivity foundation designed to support dependable operation across varied field conditions.

2. Real-time monitoring depends on end-to-end operability

QLM’s LiDAR system produces high-value methane concentration and plume data, but impact depends on being able to move data off-site consistently. Real-time monitoring and alerting also depend on the ability to keep the field system online and recover quickly if conditions change. In other words, sensing is only useful if it stays connected.

Day to day, teams need visibility into device status and the ability to troubleshoot remotely. Without that, a monitoring deployment can become a maintenance programme. QLM needed an approach that supported remote oversight and operational control as deployments scale.

3. Global deployments introduce rollout friction

For solutions that deploy across multiple countries, certification and regional acceptance become practical constraints, not paperwork. Delays in approvals can slow rollouts, complicate procurement, and increase the cost of delivering projects across different jurisdictions. QLM needed a cost-effective 4G communications solution aligned with global deployment requirements, where certification coverage can materially affect rollout speed.

Commercially, the cost of connectivity friction shows up as longer lead times, more engineering exceptions, and higher project risk. QLM wanted to simplify the deployment path so teams could focus on methane outcomes, rather than re-solving connectivity for each region.

Solution Overview

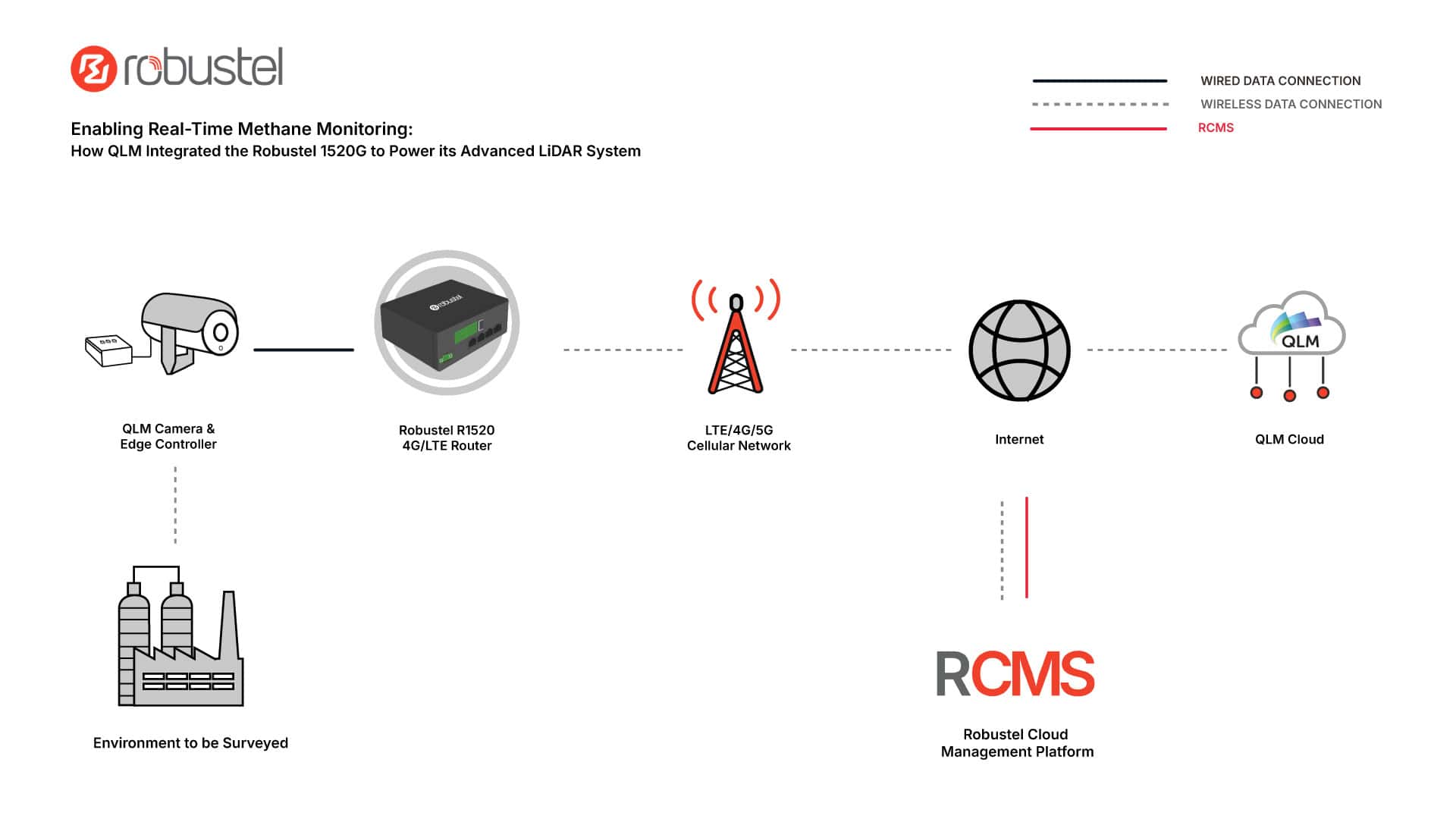

QLM integrated the Robustel R1520 Global into its field hardware as the connectivity foundation for its methane sensing LiDAR system. In the deployed solution, the LiDAR platform captures methane concentration and plume data, and the R1520 Global transmits that data over 4G/LTE to QLM’s cloud environment. QLM’s cloud platform then processes and visualises results so operators can access actionable insights, alerts, and historical trends.

This architecture supports continuous remote monitoring and helps reduce reliance on frequent manual inspections and site visits, especially across dispersed assets. As deployments scale, QLM uses RCMS to monitor and manage its deployed router fleet and support ongoing operations. Where remote access is required without fixed IP complexity, RobustVPN supports secure connectivity workflows designed to operate without requiring fixed IP services from SIM providers.

Why QLM chose the R1520 Global:

- Industrial Reliability in Demanding Environments: The R1520 Global’s rugged design and industrial-grade performance ensured dependable operation in outdoor, remote, and harsh conditions. This was a critical requirement for methane monitoring deployments where systems may run unattended and where connectivity issues can undermine the value of real-time monitoring and alerts. It also made the R1520 Global a strong fit for applications across oil and gas, agriculture, landfill, utilities, and waste management, where equipment must tolerate challenging field environments while maintaining stable telemetry.

- Global Certifications and Global 4G Frequencies: The R1520 Global is one of the world’s most certified 4G routers, supporting deployments across Europe, North America, South America, and many other regions. The $100,000+ investment already made into product certification can be leveraged by QLM to simplify deployment across different jurisdictions and reduce the friction that often slows multi-region rollouts. For a solution expected to operate globally, this certification depth supports faster approvals, smoother procurement, and a more consistent deployment model from one country to the next.

- Cyber-secure, MS Azure-based Monitoring Platform: Robustel’s router management platform, RCMS, allows QLM to monitor its estate of routers and embedded systems and apply firmware or application updates as required. RobustVPN, Robustel’s integrated VPN service, allows QLM to access both the router and the LiDAR system remotely over any SIM card, with no fixed IP required. Together, RCMS and RobustVPN support secure remote operations at scale by enabling visibility, lifecycle management, and practical remote access across distributed deployments.

Key Outcomes

Before deployment, methane monitoring programmes often rely on periodic inspections and methods that can be limited by access, conditions, and connectivity. After integration, QLM’s approach is designed for continuous field operation: data can be transmitted from the LiDAR platform to the cloud consistently, enabling operators to respond faster when emissions occur and supporting better visibility over time. Remote management capabilities also support operational consistency as deployments expand across sites, industries, and regions.

- Earlier risk visibility: Faster detection and quantification supports earlier intervention when emissions occur.

- Reduced product loss risk: Better visibility helps teams identify and address leaks faster.

- Improved sustainability outcomes: Actionable methane insights support emissions reduction and compliance objectives.

- Lower operational burden: Remote monitoring reduces the need for manual inspections and frequent site visits.

- Scalable deployment model: A repeatable connectivity and management approach supports expansion across distributed deployments.

Featured Products

Robustel R1520 Global Router

RCMS Device Management Platform